Kesar Control Systems

Stability/Humidity chamber

Introduction

A stability chamber is a device used to artificially replicate various environmental conditions by procedurally altering just two specific factors. Temperature and relative humidity. A stability chamber is thus used comprehensively in the testing of drugs & medicines in the pharmaceutical industry, to determine the basic shelf-life of the said drugs along with their resistance to environmental changes. The stability chamber can be classified into environmental chambers, temperature – humidity chambers, accelerated test chambers, and photo stability chambers, cold chambers, depending on the respective parameter of testing.

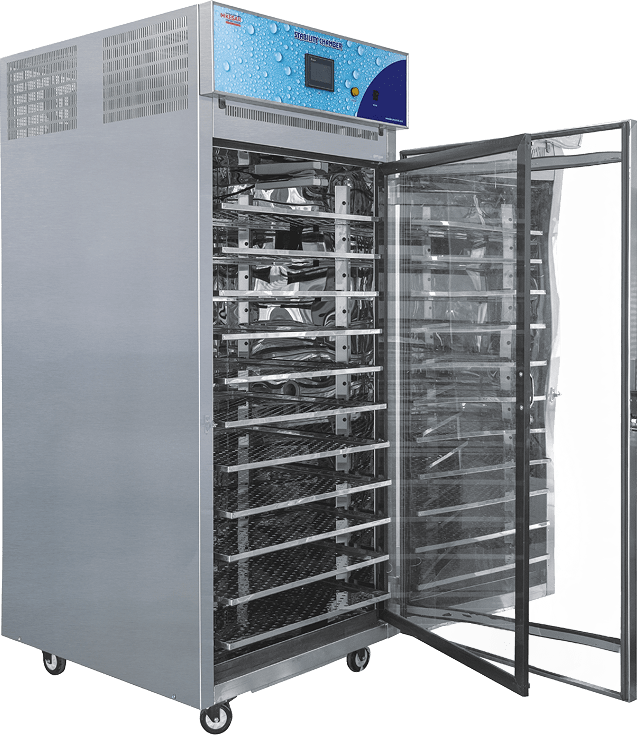

Construction

- Insulated Chamber interior made of stainless steel with mirror/dull finish.

- Exteriors with model options of Stainless steel and G.I. Powder Coating.

- Illuminated Interior with full-view glass door.

- Heavy-duty door hinges & latches to maintain a secure & uniform seal.

Other Details

Specifications

A stability chamber is a precision testing equipment that works under very tight tolerances. Temperature variations within the chamber shouldn't deviate more than 2 to 3 degree celsius. When it comes to photo stability chambers, the light emitted should be 1.2 million lux hours and it should emit more than 200 watts of UV energy for testing samples.

Full View Glass Door

A multi-pane viewing door prevents condensation & allows product view. Inner & outer doors are sealed around the entire perimeter by a silicone sponge rubber gasket.

Get Solution

Contact Kesar Control today to learn more about their Products and get a quote.

Contact NowDownload Catalogue

Features

- Heavy duty stainless steel construction

- Illuminated interior.

- Multi-pane viewing door prevents condensation to ensure a proper view.

- Heavy-duty solid stainless steel duly electro polished perforated type trays which are easy to clean and adjustable.

Optional Features

- Stand-by humidity system.

- Stand-by refrigeration system.

- Scanner.

- GSM Alert System.

- Security Alarm System.

Safety Features

- Door hinges and latches are durable and of high quality to ensure a perfectly uniform seal in the long term.

- Inner and outer doors are completely sealed by silicone sponge rubber gaskets for maximum efficacy.

Software (21 CFR Part-11 Compliance)

Log data, Event data, Audit, Trail data, E-Records & E- signatures, Graphical analysis & Data acquisition.

Trays

Heavy duty solid stainless steel duly electro polished wire mesh type trays are provide which are easy to clean, time & efforts saving, also adjustable for convenience.

Technical Specification

| Temperature Range | 20 ℃ to 60 ℃ |

|---|---|

| Humidity Range | 40%RH to 95%RH |

| Accuracy | +0.2 ℃ & +2.0% RH |

| Uniformity | +2.0 ℃ & +3.0% RH |

| Test Suitable For | 25 ℃ & 60% RH, 30 ℃ & 65% RH 40 ℃ & 75% RH, 30 ℃ & 75% RH |

| Specially designed chambers for Low Humidity conditions such as 25 ℃ 40% RH, 40 ℃ 25% RH, 30 ℃ 35% RH | |

| Control System | PLC or PID Based |

Material of Construction

| Models | Material Of Construction | |

|---|---|---|

| Interior | Exterior | |

| STD | S.S.304 Dull Finish | G.I Powder Coated |

| GMP | S.S.304 Dull Finish | S.S.304 Dull Finish |

| CGMP | S.S.316 Dull Finish | S.S.304 Dull Finish |

Sizes

| Models | Capacity (in ltrs.) | Dimensions (W X D X H) | No. of Trays | |

|---|---|---|---|---|

| Internal Width X Depth X Height (mm) |

External Width X Depth X Height (mm) |

|||

| KGOS-90 | 90 LTR | 450 X 450 X 450 | 600 X 1030 X 1060 | 2 |

| KGOS-227 | 227 LTR | 600 X 630 X 600 | 750 X 1210 X 1210 | 2 |

| KGOS-325 | 325 LTR | 600 X 630 X 900 | 750 X 1210 X 1510 | 5 |

| KGOS-400 | 400 LTR | 600 X 630 X 1060 | 750 X 1210 X 1670 | 6 |

| KGOS-500 | 500 LTR | 600 X 630 X 1330 | 750 X 1210 X 1940 | 8 |

| KGOS-600 | 600 LTR | 800 X 800 X 950 | 950 X 1380 X 1560 | 5 |

| KGOS-800 | 800 LTR | 800 X 800 X 1250 | 950 X 1380 X 1860 | 7 |

| KGOS-1000 | 1000 LTR | 800 X 800 X 1570 | 950 X 1380 X 2180 | 10 |