Stability Testing Made Simple: A Guide for Busy Pharmaceutical Labs

What is Stability Testing?

Stability testing is a crucial process in the pharmaceutical industry designed to evaluate how a drug product maintains its quality over time under various environmental conditions. It assesses the product's safety, efficacy, and overall quality throughout its shelf life.

Importance of Stability Testing in Pharmaceuticals:

Stability testing ensures that pharmaceutical products remain effective and safe for consumption until their expiration date. It also helps in determining proper storage conditions and supports regulatory compliance.

Purpose of This Guide:

This guide aims to simplify the stability testing process for pharmaceutical labs, offering practical advice and strategies to manage testing efficiently while meeting regulatory standards.

Understanding the Basics of Stability Testing

What is Stability Testing?

Definition and Overview:

Stability testing involves monitoring a drug's quality over time under controlled environmental conditions, such as temperature and humidity. This process helps in predicting the product's shelf life and effectiveness.

Types of Stability Testing

-

Long-term Stability Testing: Conducted over extended periods to assess the product's stability under normal storage conditions.

-

Accelerated Stability Testing: Performed under elevated conditions to predict long-term stability in a shorter timeframe.

-

Stress Testing: Evaluate the drug's stability under extreme conditions to understand its behavior under stress.

Why Stability Testing is Crucial for Pharmaceutical Labs

Ensuring Product Safety and Efficacy:

Stability testing confirms that a drug product remains safe and effective throughout its intended shelf life, preventing potential health risks to consumers.

Regulatory Compliance Requirements:

Adherence to stability testing regulations ensures that pharmaceutical products meet the standards set by regulatory agencies, facilitating market approval and maintaining compliance.

Impact on Shelf Life and Storage Conditions:

Determining the product's shelf life and optimal storage conditions through stability testing helps in proper labeling and ensures that products are stored under the right conditions.

The Stability Testing Process Simplified

Step-by-Step Overview of Stability Testing

Sample Preparation and Selection:

Proper sample preparation and selection are essential for obtaining accurate stability data. Ensure that samples are representative of the product and prepared following standard procedures.

Storage Conditions and Testing Protocols:

Establishing precise storage conditions (e.g., temperature, humidity) and following standardized testing protocols are crucial for obtaining reliable results. Regular monitoring of these conditions is necessary to ensure compliance.

Common Challenges and How to Overcome Them

Handling Multiple Products and Batches:

Managing multiple products and batches can be challenging. Implementing efficient workflows and using automation can help streamline the process and reduce the risk of errors.

Managing Time and Resources Efficiently:

Efficient resource allocation and time management are critical. Prioritize tasks, use automated systems, and optimize laboratory workflows to enhance productivity and reduce bottlenecks.

Tools and Techniques for Efficient Stability Testing

Essential Equipment and Technology

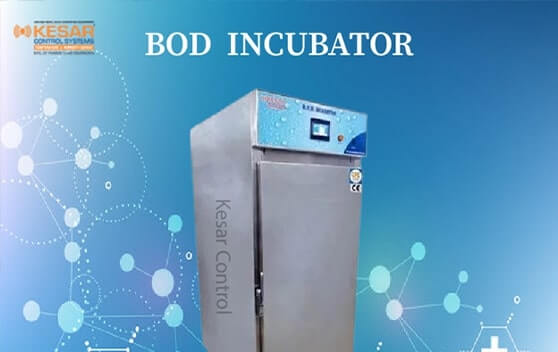

Temperature and Humidity Chambers:

These chambers simulate various environmental conditions to test the stability of pharmaceutical products under controlled settings.

Analytical Testing Instruments:

Instruments such as HPLC (High-Performance Liquid Chromatography), GC (Gas Chromatography), and spectroscopy are used to analyze the chemical composition and stability of products.

Best Practices for Streamlined Testing

Automating Stability Testing Workflows:

Automation can enhance efficiency and accuracy by reducing manual errors and speeding up testing processes. Implement automated systems for sample handling, data collection, and result analysis.

Leveraging Predictive Analytics:

Use predictive analytics to forecast potential stability issues and optimize testing procedures. This approach can help in identifying trends and making data-driven decisions.

Regulatory Considerations for Stability Testing

Key Regulatory Guidelines

ICH Guidelines:

The International Council for Harmonisation (ICH) guidelines, such as Q1A (stability testing), Q1B (photostability testing), and Q1C (stability testing for new dosage forms), provide standards for stability testing procedures.

FDA and EMA Requirements:

The FDA and EMA have specific requirements for stability testing to ensure drug safety and efficacy. Adherence to these guidelines is necessary for regulatory approval and market access.

Country-Specific Regulations:

Different countries may have unique stability testing regulations. Stay informed about regional requirements to ensure global compliance.

Compliance Strategies for Busy Labs

Adapting to Regulatory Changes:

Stay updated with regulatory changes and adapt testing procedures accordingly. Regularly review guidelines and integrate new requirements into your testing processes.

Audits and Inspections: What to Expect:

Prepare for audits and inspections by maintaining thorough documentation and ensuring compliance with all regulatory requirements. Understand what to expect during these evaluations and address any potential issues proactively.

Case Studies and Real-World Examples

Success Stories from Pharmaceutical Labs

How Lab X Streamlined Their Stability Testing Process:

Explore how Lab X improved its stability testing procedures by implementing new technologies and workflow optimizations.

Innovative Approaches to Overcome Testing Challenges:

Learn from innovative approaches that helped other labs overcome common stability testing challenges and improve efficiency.

Lessons Learned from Stability Testing Failures

Common Pitfalls and How to Avoid Them:

Identify common pitfalls in stability testing and learn strategies to avoid them, ensuring more reliable results.

Key Takeaways for Busy Labs:

Gain practical insights and key takeaways from real-world examples to enhance stability testing practices in busy pharmaceutical labs.

Conclusion

Stability testing is essential for ensuring the quality and safety of pharmaceutical products. By understanding the basics, overcoming common challenges, and leveraging modern tools and techniques, busy labs can streamline their stability testing processes and maintain compliance with regulatory standards.